WELCOME TO GANRAJ ENTERPRISES

WELCOME TO GANRAJ ENTERPRISES

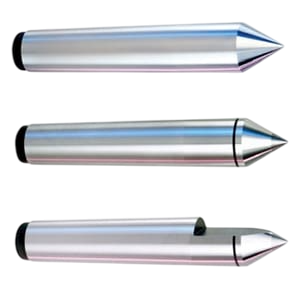

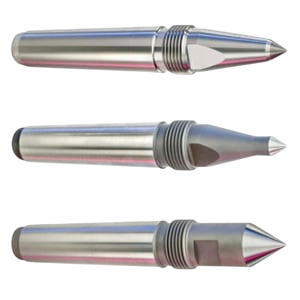

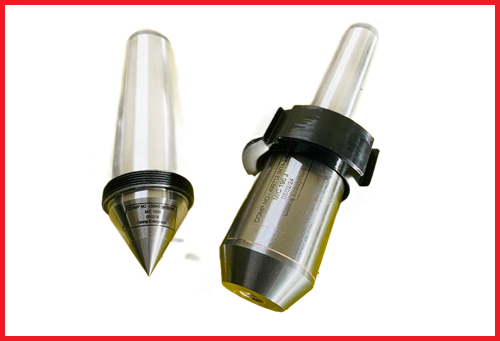

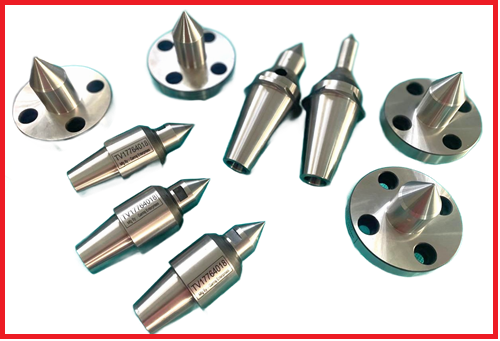

Our Centres are manufactured as per specification IS: 2289-1976. Our Dead Centres are manufactured in order to achieve the most accurate in accuracy and strength. These are made from Bearing Steel hardened and tempered to hardness of 58 to 62 HRC. Dead Centers are available in MT-1, MT-2, MT-3, MT-4, MT-5 and MT-6 models. Dead Centres are available in Carbide Tips, HSS tips. Specially shaped and designed Dead Centres are also manufactured against request. No piece is delivered without thorough inspection.